Empower Your Production

Our goal is to provide our customers with the ability to fill their own products, giving them the opportunity and freedom to easily control production.

Our reputation for being tough and reliable is a direct reflection of the engineering and design team’s ambition to build high quality, high performance equipment. The company’s European influence and North American philosophy are showcased directly through the superior characteristics and craftsmanship of our equipment.

Machine Series

Powered by Precision Manufacturing

Our Professionalism Builds Trust

Trusted by Global Brands

Every Encounter With Our Client

Your Best Choice of Filling Partner

Global Presence

King Pack partners with top global brands, delivering innovative and sustainable packaging solutions worldwide.

Common Pitfall

There are different things to consider when purchasing machinery from China, There are many great machines out there.

However, some suppliers offer low-quality machines that need to be avoided. It is very importamt to make sure that you are getting the high quality of craftsmanship machine. You need to take some steps to ensure that you are not being cheated by scam.

On-site visits are necessary if conditions allow

Selection of food-grade raw materials.

With professional and reliable component suppliers for their equipment.

After-sales details need to be thorough.

The Process Flow & Duration Estimation

Please note that the final cost depends on the customized service you require. the specifications of the raw materials used, the relevant national laws.

and the distance of transportation. Take the example of booking a tall container of products:

Step1: Confirm solution and your requirments(3-5 days)

To recommend the most suitable filling, capping, and labeling machine, we need to understand your specific needs. Please provide the following details:

1.Bottle size

2.Bottle type (material and shape)

3.Cap type

4.Target production capacity

Step2: Tube samples and Payment (1-5 days)

After the solution is confirmed:

1.You will send us your bottle and cap samples for design confirmation.

2.We will prepare a proforma invoice.

3.You arrange the advance payment (typically 30% T/T deposit).

Step3: Production(30-40 days)

Upon receipt of your samples and payment:

1.We begin machine design and manufacturing.

2.During production, our QC team will conduct regular inspections to ensure quality.

3.Final testing will be conducted before packing.

Step4: Shipping (20-30 days)

You can choose from the following shipping methods:

By Air: Fast (3–5 days), higher cost

By Sea: Economical (20–30 days), slower delivery

We will assist in booking and document preparation (e.g., B/L, invoice, packing list).

Our Core Component Suppliers

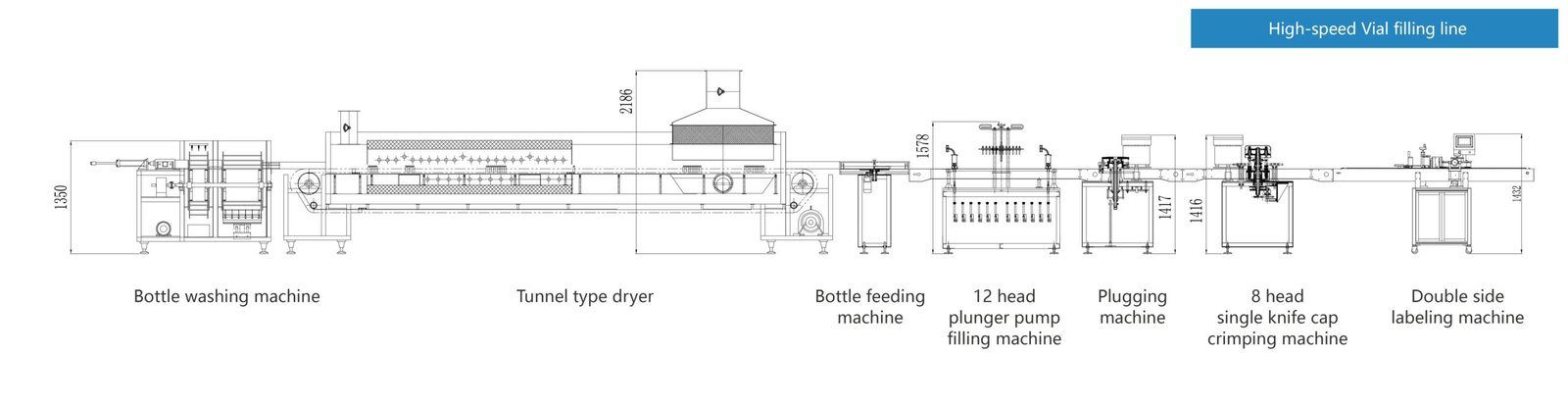

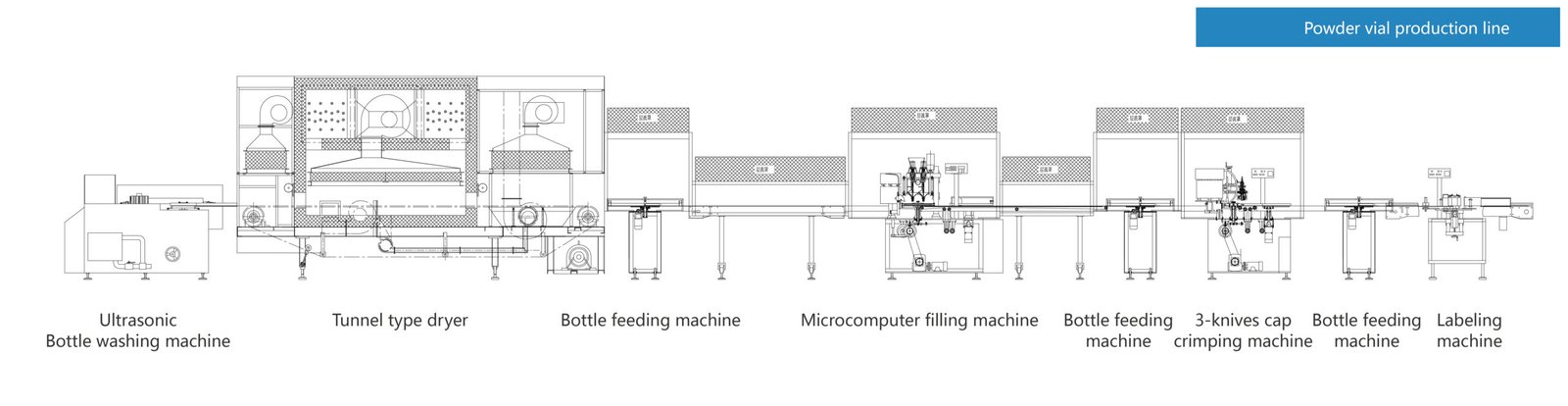

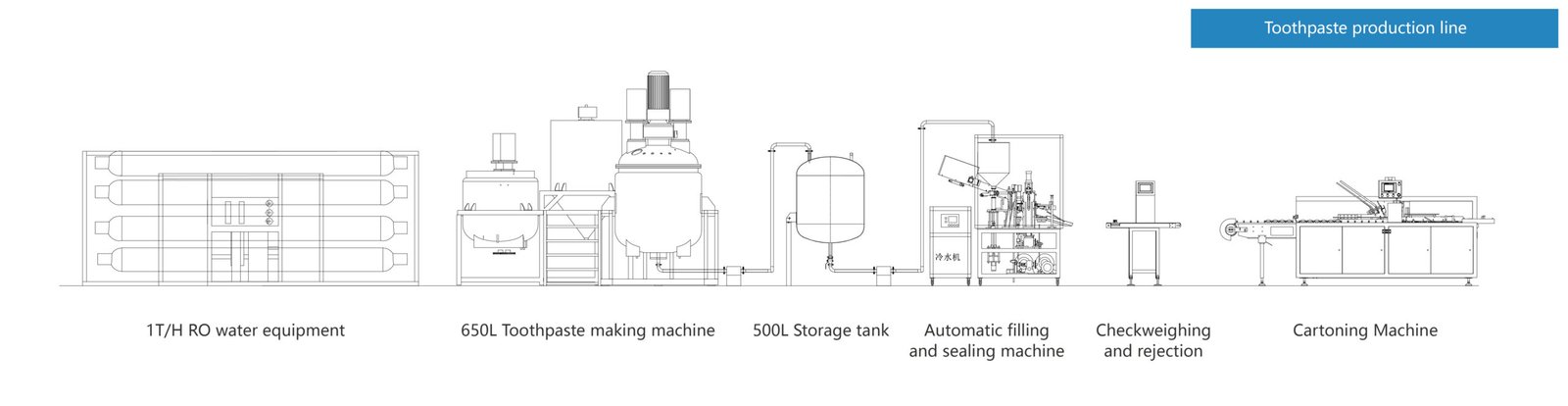

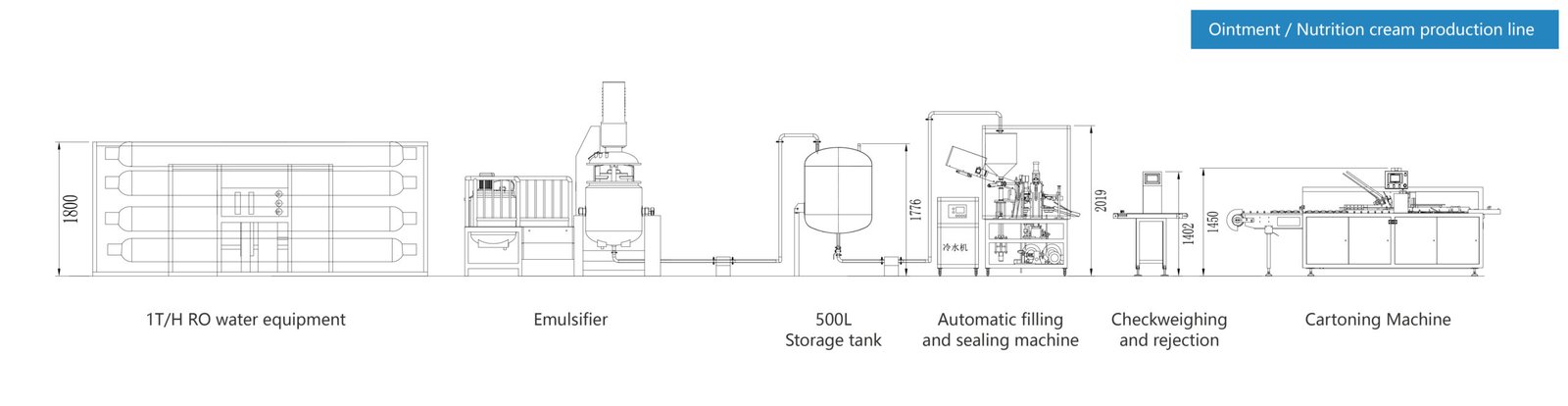

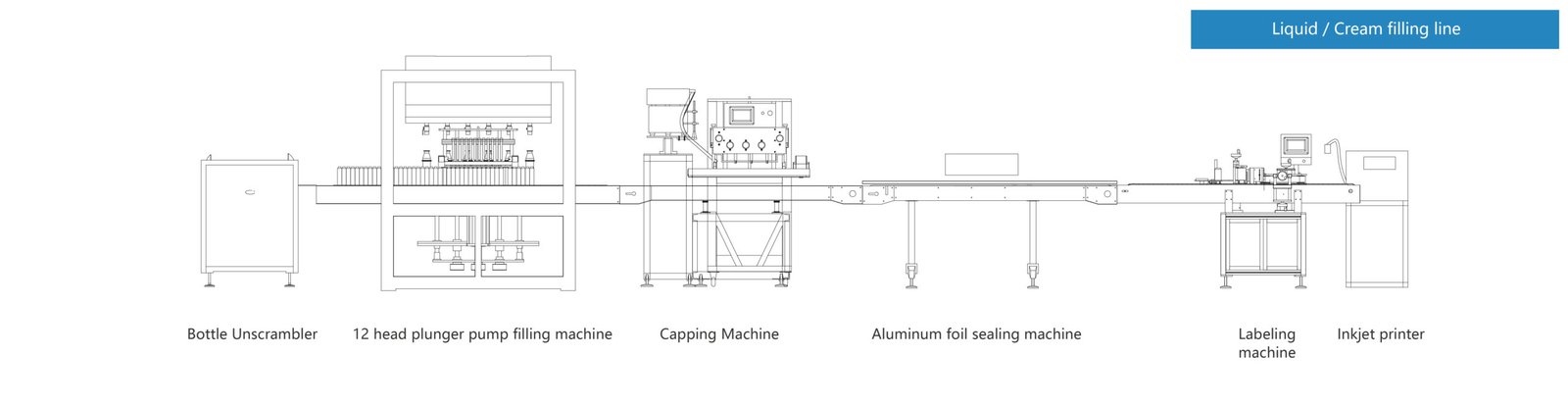

A-Z Turnkey Solutions

At King Pack, we understand that every customer has unique packaging requirements.

That’s why we offer customized packaging solutions tailored to your specific products and production needs. Our filling, capping, and labeling machines can be fully customized to integrate seamlessly with your existing production line. Whether you run a small workshop or a large-scale manufacturing facility, King Pack is committed to delivering the right packaging machinery that fits your operation perfectly.

We move forward together with our customers — with efficiency, precision, and flexibility at the core of everything we do.

From Beginner to Pro

Small and startup pet pharmaceutical manufacturers face constant pressure to control costs while maintaining high product quality. Manual or semi-automatic...Read More

External parasite drops, such as flea and tick treatments like Frontline, are critical products in pet healthcare. Proper manufacturing ensures...Read More

Pet healthcare products are no longer niche items. Ointments, creams, and nutrition pastes now play a major role in daily...Read More

The veterinary pharmaceutical market continues to grow at a steady pace. Pet owners expect safer products, accurate dosing, and consistent...Read More

The pet pharmaceutical and care market is expanding rapidly. Pet owners increasingly demand safe, effective, and high-quality medicines. This makes...Read More

Recently, King Pack Machinery, a professional manufacturer of filling and packaging equipment, welcomed an Australian client to visit our factory...Read More

The global toothpaste market was valued at about $22.3 billion in 2025 and is forecast to expand at a compound...Read More

Good Manufacturing Practice standards protect consumers from contamination, ensure product consistency, and support regulatory compliance. For toothpaste manufacturers, GMP-compliant equipment...Read More

The global tube packaging market reached $9.91 billion in 2020 and is projected to hit $16.11 billion by 2028, growing...Read More

The global cartoning machines market is projected to grow to over $13.58 billion by 2034 at a compound annual growth...Read More

Contact Us

FIll out the form below and we will cantact you as soon as possible